Driving Productivity and Quality with Expert Automation Integration

Who We Are

Since 1997, we’ve been at the forefront of intelligent automation, designing and integrating advanced robotic systems that solve complex manufacturing challenges. As a trusted UK-based automation partner, we specialise in bespoke robotic solutions for industries including Automotive, Aerospace, Packaging, Logistics, and General Manufacturing. From robotic welding and precision handling to adhesive application, machine vision, and inspection — we deliver complete, in-house engineered systems that boost productivity, quality, and safety. Backed by decades of experience, a multi-skilled technical team, and a partnership-first approach, we turn automation into a powerful advantage for forward-thinking manufacturers.

Coming Soon

Big changes with our new website, watch this space and follow us on Linkedin for more updates.

A Partnership-First Approach

At the heart of every successful automation project is a strong partnership. We don’t just deliver machines — we collaborate from day one to build tailored automation solutions that work in the real world. By working closely with your engineers, operators, and leadership teams throughout every stage — from concept to commissioning — we ensure the final system aligns perfectly with your goals. We believe automation should be embraced, not feared; that’s why we focus on early engagement, transparent communication, and practical integration.

It’s this partnership-driven process that turns automation from a risky investment into a long-term competitive advantage.

Support That Delivers Results

True automation success doesn’t end with a machine delivery — it starts with complete support from concept to full production. We provide a fully integrated, end-to-end service that guides you through every phase of the project: from early design discussions and build-phase collaboration, to installation, operator training, and beyond.

By involving your team early — especially the operators and engineers who will run the equipment — we help close the loop between vision and reality. Our approach ensures a smoother handover, quicker ramp-up, and long-term productivity gains, all backed by the confidence that your staff are equipped and ready from day one.

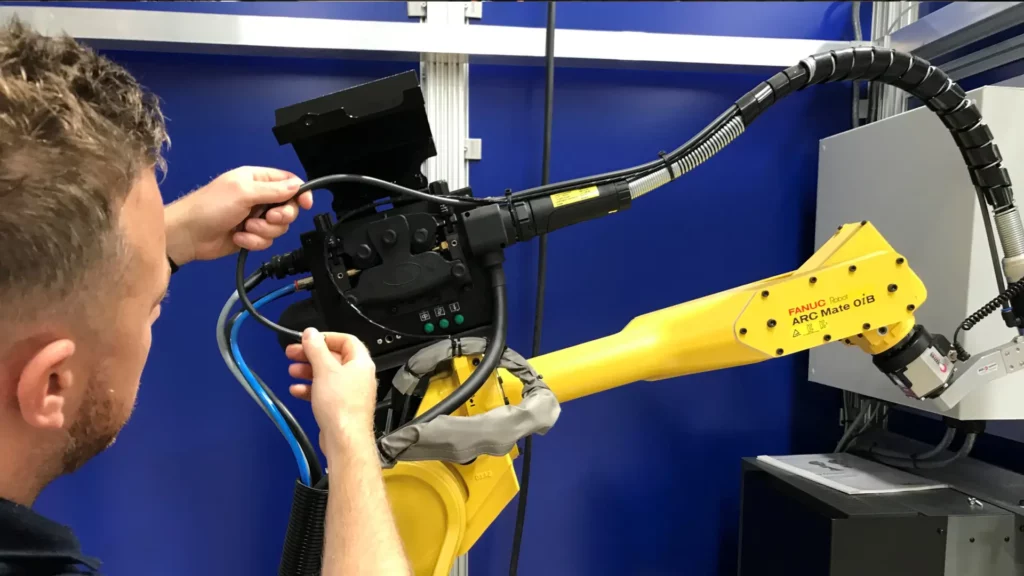

On-Site Integration & Commissioning

We don’t just deliver automation — we make sure it performs exactly where it matters most: on your factory floor. Our on-site integration and commissioning process ensures every system is fully tested, fine-tuned, and production-ready before handover. We run real parts, validate quality standards, and optimise performance to your exact requirements. From pass-off to site acceptance, we work side-by-side with your team to guarantee seamless startup and long-term reliability. It’s not just about getting machines running — it’s about delivering confidence, capability, and measurable results from day one.

Sector-Specific Automation Capabilities

No two industries operate the same — and neither should their automation. With over 25 years of experience delivering sector-specific robotic systems, we engineer solutions that align with the exact technical, regulatory, and operational demands of each manufacturing environment. Whether it’s automotive precision welding, high-throughput logistics handling, aerospace compliance, or flexible systems for white and yellow goods, our automation is built to spec, built to scale, and built to last. We don’t adapt your process to the technology — we engineer technology to elevate your process.

Tooling, Fixtures & Bespoke Engineering

Bespoke tooling and fixtures are the backbone of any successful automation system — and we design and manufacture every one in-house to match your exact components, processes, and production goals. Our bespoke engineering ensures parts are held securely, accurately, and consistently, enabling seamless integration with robotic systems and repeatable high-quality results. We work closely with clients from the start to validate part suitability, avoid automation pitfalls, and ensure the entire solution operates as a cohesive, high-yield unit. Because in automation, it’s not just about the machine — it’s about how well every part fits together.

Specialist Expertise

When it comes to advanced automation, technical depth isn’t optional — it’s essential. Our strength lies in specialist expertise across robotics, control systems, vision technology, precision joining, and machine safety. From programming 6-axis robots for assembly to developing PLC architectures with integrated diagnostics, our team brings deep subject-matter knowledge to every project. We don’t just follow standards — we help set them, ensuring each system is technically robust, future-ready, and aligned with your exact performance goals.

Full In-House Capability

Our fully in-house capability means every stage of your automation project is handled by our own expert team — from mechanical and electrical design through to build, programming, and commissioning. By eliminating the need for third-party suppliers, we ensure tighter integration, faster turnaround, and complete technical alignment from concept to completion. With everything from PLC programming to robot simulation and safety validation carried out in-house, we maintain full control over quality and performance — delivering solutions that are precise, dependable, and production-ready from day one.

Training, Documentation & Safety Compliance

Automation is only as effective as the people who operate it — and the standards that support it. That’s why we provide comprehensive, role-specific training, fully detailed technical documentation, and rigorous safety compliance with every system we deliver. From operator familiarisation to engineer-level fault diagnostics, we ensure your team is fully prepared and confident. All systems are designed and validated to meet CE/UKCA marking and relevant ISO/EN standards, with all safety documentation and declarations supplied as standard. The result? A safe, compliant, and maintainable system — ready for immediate, effective deployment.

Passion for Innovation, Commitment to Excellence

At the heart of everything we do is a deep-rooted purpose: to empower industries through intelligent automation that enhances productivity, quality, and workforce satisfaction. Our people are the driving force behind this vision. With expertise across robotics, control systems, engineering, and more, our team is dedicated to solving real-world challenges with innovative solutions. Through continuous learning, a culture of collaboration, and a commitment to customer success, we ensure that every project we take on is not just a job, but a mission to make a meaningful impact.