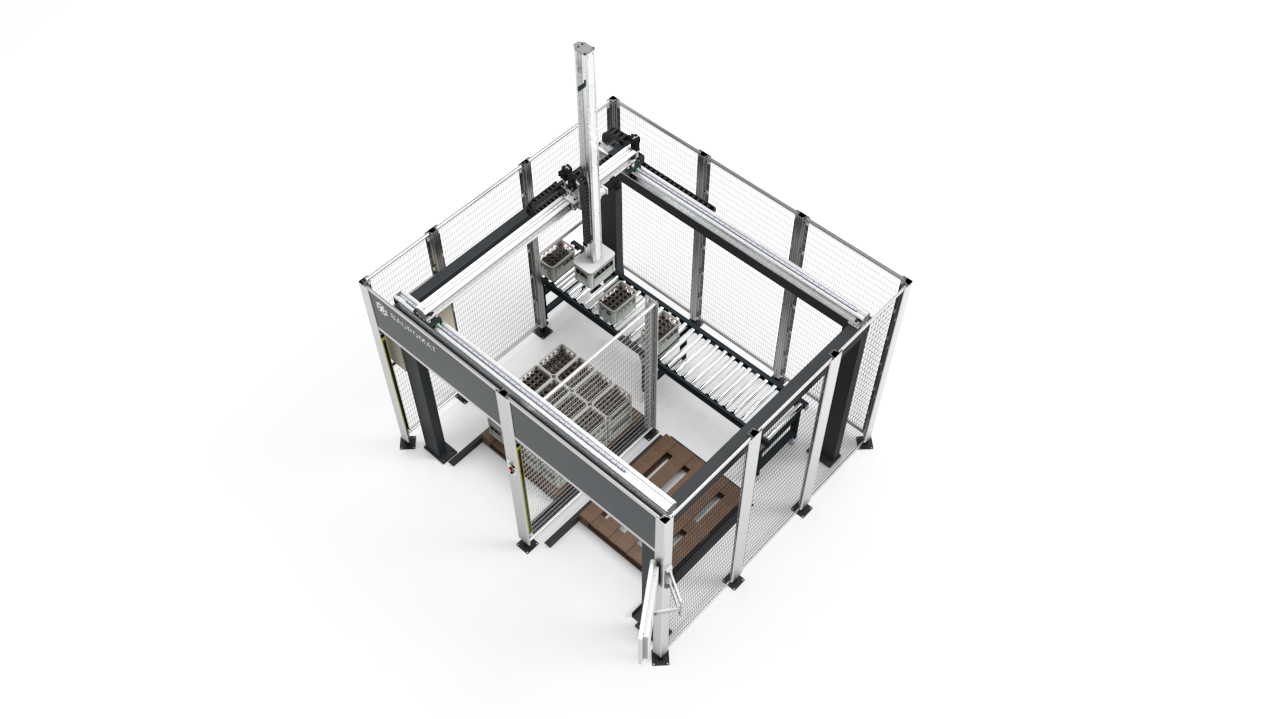

Compact Modules for Reduced Footprint

Space is important, whether you are a huge factory with multiple lines, or a small workshop with limited areas, space must be optimized. With Bauromat’s automated packing solutions space does not have to be a concern.

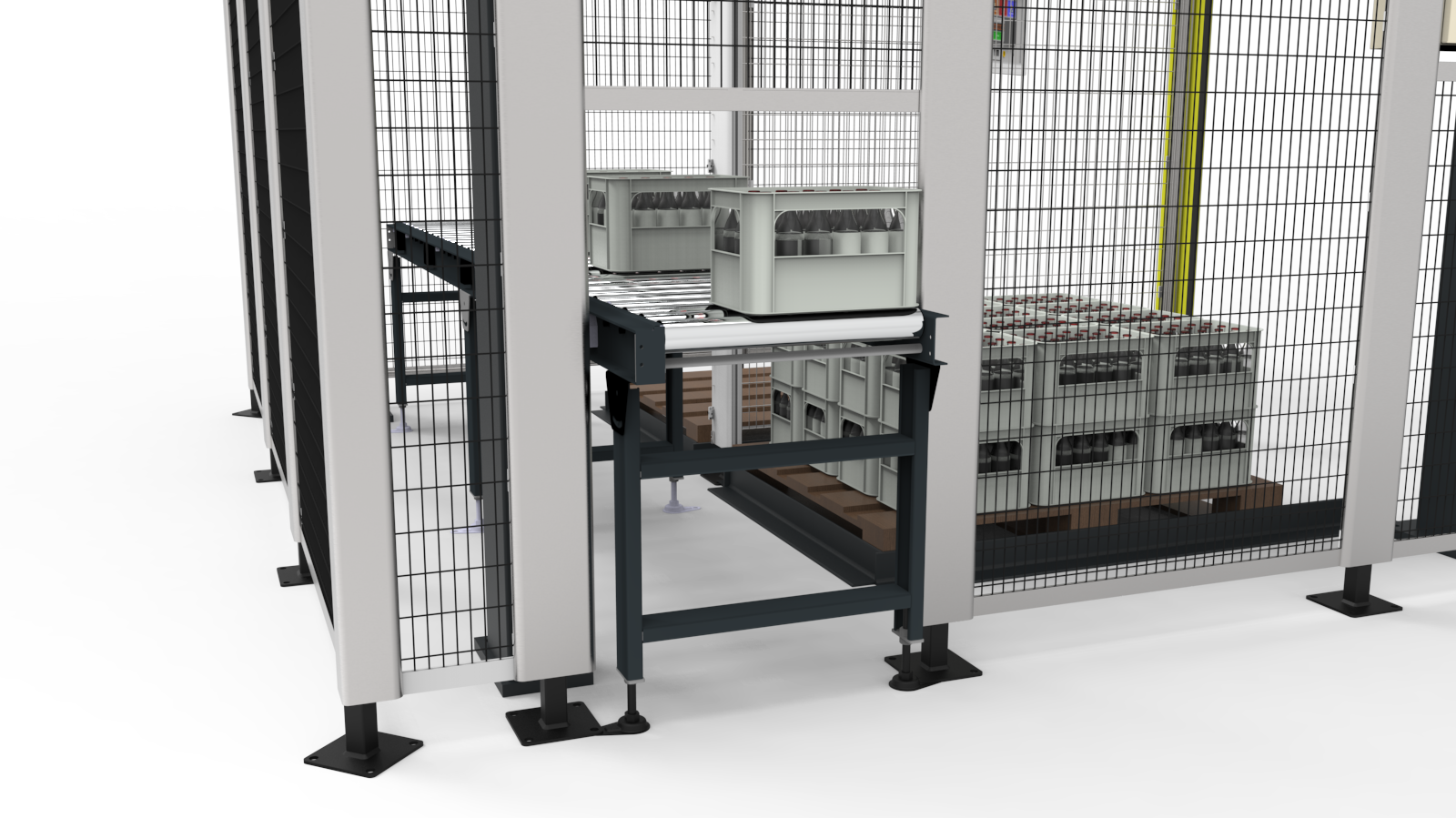

Not only is the robotic gantry more space efficient when compared with traditional six axis robots, its design is modular meaning it can be adjusted to fit into spaces or all sizes. In time, if things change and you need an extension on the system, or part of it reducing, the Bauromat automated packing solution is easily adapted with guarding and other essential modules added and taken away.

Single or Multiple Pallet Configurations

Leading on from the first point, the modular nature of the Bauromat automated packaging solution means that if you require a system with a single pallet load, or multiple pallet loads, the option to extend or reduce is there for minimal cost and maximum ease.

There is no need to make a full system overhaul from the word go, if you would like to slowly introduce automation, single configurations are the ideal solution. Likewise, if you are ready for full line automation, our multiple pallet models give you the peace of mind.

State of the Art HMI Software

With all of our systems, be them arc welding, material handling, CNC machining or our all new automated packing solutions, we always offer our state of the art SIGMATEK HMI, designed for purpose with ease of use for the user at the forefront.

Featuring secure logins for all level of users, all parts of the system can be monitored with ease. The HMI also contains electronic versions of all manuals and instructions, while Bauromat can also support with remote access meaning our engineers can check the system’s status before even committing to a site visit. Get in touch for more info.

Automated Packaging With New or Existing Lines

We like to make integration automation as seamless as possible and save you from having any unnecessary stoppages in your production time. If you have an existing line and still want to keep your current conveyors and/or in-feeds and exits, that’s absolutely no problem, we can design the gantry and safety around your existing line.

But, if you require full automation overall, we can provide each part of your system, sourcing from the best suppliers throughout the industry, with us as your single and only point of contact at all stages of the project.

End Effector Flexibility

Automated packing can be extended out to any number of products. If they come in boxes, bottles or bags, chances are our automated packaging solution can help you get more efficient and increase your productivity. Luckily, we offer full flexibility on our gantry end effectors meaning whatever you need to pick up we’ll ensure it can be done, be it through vacuum gripper, electrical or servo.

Have a preference and want an off the shelf model? No problem at all, we work with our partners to ensure you get the end effector you need. Not sure what you need? We have a design team dedicated to making the impossible possible and have a proven track record or developing grippers for a range of products.

Send us your question & let us know how we can help you

Bauromat

Stafford Park 6

Telford

TF3 3AT

United Kingdom