A Concept that’s more Than a Solution

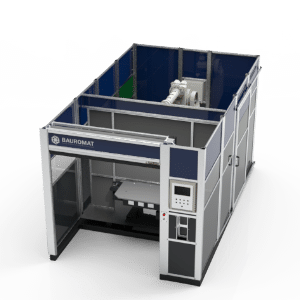

Although the BAURO-Spot systems are referred to as standards, we like to use the word ‘concepts’. This is because although there may be similarities, no two robotic systems will ever be the same. The Spot systems are an idea that, together with the customer, can be refined for the best results possible. Different options, alternative access doors, even a different shape, whatever requirements the customer has, the BAURO-Spot concepts allow us to provide the end-user with the perfect solution.

The right system for me?

After over 20 years of experience, we can work that out for you. The last thing we expect is for the customer to do the hard work. Instead, what we do is work closely with them and the part they require spot welding. This, twinned with understanding the volume and expectations allow us to work out the best possible solution.

Position, Plug In and Play...

Like all standard Bauromat systems, the BAURO-Spot concepts are designed for ease of use. Featuring a base designed with fork life holes, on delivery to get your system up running it is as simple and moving it into position, connecting power and turning it on. For larger Spot systems, the base can also be designed in half, preventing any headaches when trying to fit the system through tight workspaces.

Meet the BAURO-Spot Family...

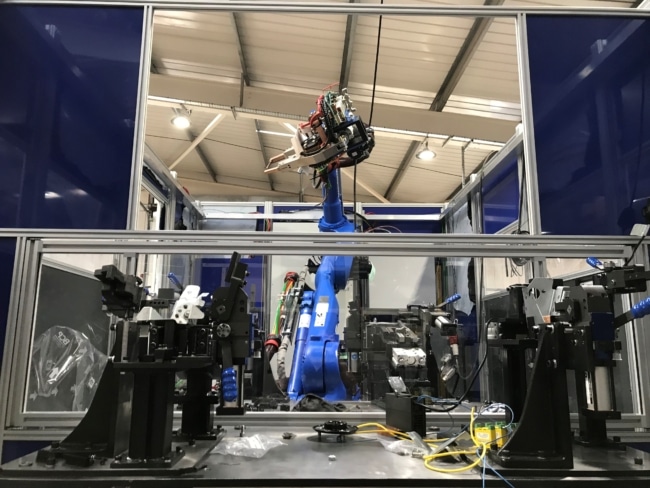

BAURO-Spot 2000

BAURO-Spot 2000 is a single robot system based on a two-station positioner that can be either manual (2000M) or powered (2000P). This system allows for increased output as parts can be loaded and unloaded by a human worker, while the system spot welds parts on the other side of the positioner. This is an ideal solution for most spot welding applications that require high volumes and consistent output.

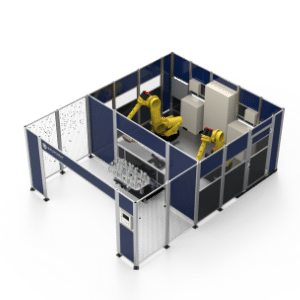

BAURO-Spot 2000 Twin

Due to the high volumes often required in industries suited to spot welding. The BAURO-Spot 2000 Twin is based on the same principle as the BAURO-Spot 2000, featuring a choice of powered (2000P) or manual (2000M) turntables, but instead of featuring just one robot, the system is designed to house two, doubling its efficiency and output. With a slightly wider base and more room for the additional controls, the BAURO-Spot 2000 Twin allows for more parts to be welded per cycle increasing the user’s productivity.

Let’s find the best BAURO-Spot product for you...

BAURO-Spot FAQ's

BAURO-Spot is a range of automated robotic spot & resistance welding concepts that are best suited for those applications. Depending on project specifics, our Spot systems can be adapted to suit more than just spot welding. Contact us for more.

If you require a resistance or spot welding robot system, then BAURO-Spot automated robot solutions can be a cost-effective solution to your requirements. Talk with Bauromat today to discuss which BAURO-Spot solution is best for you.

From completion to manufacture, a BAURO-Spot system can be installed in as little as a day. This allows things such as guarding to be rebuilt and the robot to be programmed. Larger and more bespoke systems may require more time to be installed.