Tend to it, Whatever the Size

From small metal pressings and tools to huge automotive assemblies, whatever machine requires tending, and whatever the size of the component, Bauromat can assist in providing an automation solution for you. If it’s as simple as programming a robot safely to tend to an existing machine or a complete bespoke automation solution in which all aspects are designed and manufactured, any variety of machine tending solutions can be manufactured for any type of requirement.

This applies to a variety of industries too, from heavy fabrication and automotive to logistics and end of line solutions, any machine that requires automation to help it run more efficiently is ideal for machine tending solutions.

There may be a CNC machine that needs to be consistently loaded and unloaded or a metal pressings line that needs parts moving to and from, whatever it is, if there’s a machine that’s part of a production line, automated machine tending is the solution to get efficiency and consistency to the highest possible levels.

It Starts At Your Parts

As with all Bauromat systems, the most important thing is the part and understanding the size, quality and volume. It’s these key findings that allow us to come up with the best possible requirements for your solution; the type of robot, the best possible end of arm tooling, the correct levels of safety, everything to make your automation create higher efficiency levels. Find out more about how we integrate with the customer from day for the best possible automation solution.

Getting the Right Robot

With a diverse range of robots on the market, it’s difficult to know exactly what robot will be best suited to your job, but that’s where Bauromat comes in. With over 20 years experience and have produced systems of all shapes, sizes and requirements, we know exactly what robot to use. Part of our ‘integration from day one’ philosophy means that understanding your part and your expectation gives us everything we need to know to be able to provide the correct robot. From collaboratives, SCARAs or industrial robots of all sizes, all you need to tell is if you have a manufacturer preference or not.

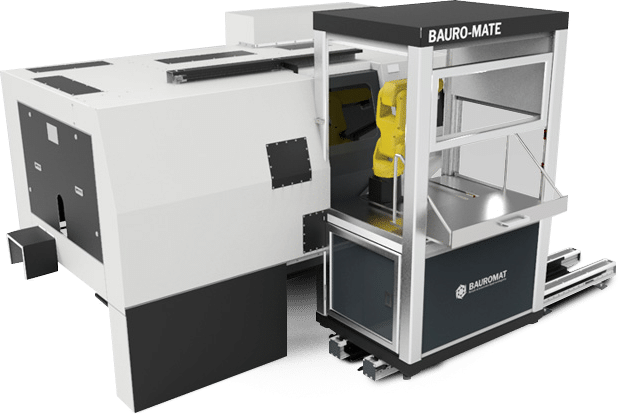

BAURO-MATE

Bauromat has an excellent machine tending automated system, through its flexible solution, BAURO-MATE. Designed with an open side, BAURO-MATE is an ideal machine tending robotic solution for companies with existing machines, looking for cost effective automation. With a host of flexible options, including drawers, conveyors, turntables and hatches, BAURO-MATE can be manufactured to suit whatever machine tending requirements are needed with full flexibility on robot brands. For parts of up to 10kg, BAURO-MATE is the ideal machine tending solution for a variety of machine tending applications.

Want to find out more about our Machine Tending possibilities? Contact us below

Machine Tending FAQ's

The best robot depends on specific applications. Larger handling robots are usually the robot of choice when large objects or pallets need to be moved from machines, however, if the machine being tended only contains small parts, a smaller robot would be selected. These conversations can be had in initial project discussions.

Industrial robots are powered by a series of drives and gearboxes controlling each individual axis. The robot is programmed using a teach pendant which controls each axis individually, recording positions as it moves from point-to-point so that when it runs automatically the robot repeats the movement over and over again.

Industrial robots are programmed through a teach pendant. A bit like a tablet, the teach pendant controls all aspects of the industrial robot. When being programmed, the users control each axis, moving the robot from point-to-point and recording each move. These are saved into a program and can be run automatically by the industrial robot over and over again.