Automated Pick & Place Solutions

Struggling to meet the demands of your production? Are you constantly chasing moving targets or looking to make your end of line packaging quicker?

A robot system focused on pick & place is going to be highly advantageous for you.

Available in all shapes and sizes, from SCARA and collaborative robots, to large handling industrial robots capable of moving objects of over a tonne, the options are almost endless.

Are you looking at finding out more about pick & place or material handling robots? We’ve answered some of the most frequently asked questions below.

Picking The Right Solution

If you’re in pharmaceuticals, food packaging, automotive, or logistics, automated pick & place is the ideal robotic solution for you to increase your efficiency, run at a greater output, and generally future proof your business. Bauromat has the ability to manufacture small, robot only solutions to integrate into existing automated lines, or can manufacture a complete bespoke turnkey solution automating all aspects of requirements.

With leading partnerships in a variety of industries, you’ll be safe in the knowledge that your automation system features products of the highest quality. We can integrate all types of robots, from SCARA to traditional six-axis industrial and collaborative robots, these systems also require a camera or vision system. Enabling the robot to handle parts accurately and consistently, most robot manufacturers have their own vision systems, but Bauromat also works with standalone vision system providers and will work closely with the end-user to get the best possible solution.

What is a pick & place robot?

Designed to move an object from one place to another, or ‘pick it up and place it back down in another position’, pick & place robots are an important part of any manufacturing process. From assembly or sorting, to packaging or loading, pick and place robots allow businesses to automate relatively simple processes, with significant increases in efficiency.

Depending on the size of the components being handled and moved helps you find the best possible pick and place robot. Your automation partner should discuss this with you during the initial stages.

The Best Jobs For Pick & Place Robots?

Pick & place jobs can vary in size and scale. As long as you have parts or components that need to be moved from one place to another, then a pick & place robot system is going to be ideal.

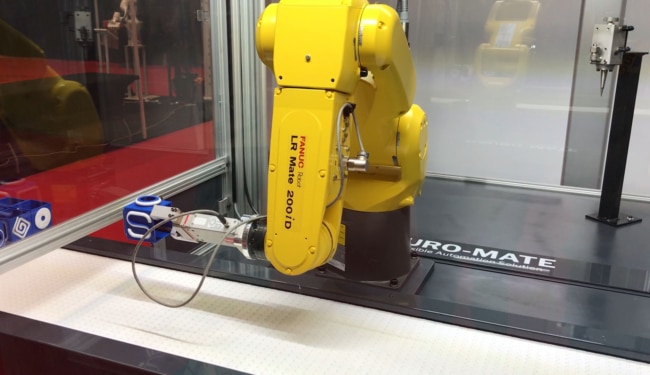

If your parts are small, and are part of a manned process, you might want to consider a small handling robot such as a Fanuc LR Mate, or even a collaborative robot (check with your automation provider if the application is suited to a collaborative robot).

With larger parts, or those of smaller volumes such as those used in automotive, you might want to consider larger robots. It’s all about understanding your specific requirements.

Let’s Work Out Your Solution Together

Our philosophy put’s the customer’s requirements at the heart from the first meeting and onwards until commission and installation. We call it ‘integration from day one, and like our automated solutions ensure high-quality communications with the customer at all stages of the process. Understanding the process and the requirements is key, and in learning this through the initial conversations with the customer, we ensure the best final results possible. You can find out more about our philosophy and how we work closely with the customer from enquiry, through to design, manufacture, and commission.

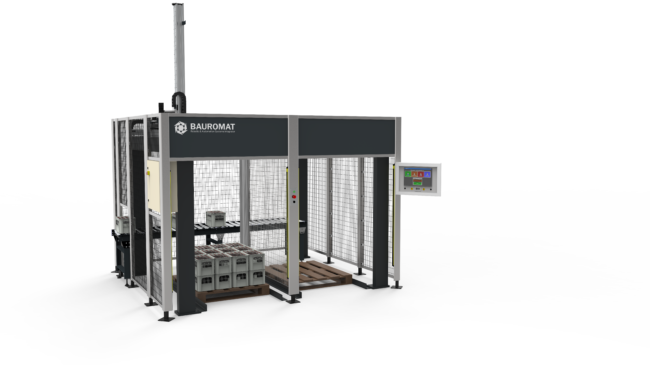

BAURO-MATE

Bauromat’s flexible automation solution BAURO-MATE is the ideal automation system for pick and place requirements. Designed to be applied in a number of industries, for a number of applications, BAURO-MATE is a blank canvas to be customised specifically for pick and place applications. Featuring two independent halves, or as a single open-sided robotic solution BAURO-MATE can easily be integrated into existing lines or can be designed from the ground up as a bespoke solution. Able to house a small handling robot or fast-moving 4-axis SCARA robot, BAURO-MATE is your next robotic companion.

What Are The Benefits of Pick & Place Robots?

Like all automation systems, the benefits of a pick & place robot and larger system are extensive.

Pick & place robots come in all shapes and sizes. With wide reach and slim construction they can be extremely accurate and versatile. This means that work can be completed much quicker and to a far greater standard.

They are also much quicker than a human equivalent. With the potential to pick up multiple parts at once, efficiency is increased significantly, helping your business grow.

Pick & Place: What Are The Best Material Handling Robots

It all comes down to your specific requirements. Are you looking at handling large pieces of equipment in small batches? Then you’ll probably need a larger robot and a more bespoke end-of-arm gripper.

If you’re focusing on smaller parts of higher volume, you’ll need a robot to suit.

Industrial robots come in all shapes and sizes and one of the key characteristics is the payload that they can handle. The robot you use needs to reflect the weight of the parts it will be handling, narrowing the options you can choose.

Material Handling Robotics: What is it?

Material handling robots and pick & place robots are essentially the same thing with different names. Typically, pick and place refers to smaller processes that require high speed and high volume, whereas material handling is about manipulation and movement of individual components.

Any time an automated process of moving a part from a-to-b is completed or is ‘handled’ by a robot it can be considered material handling.

To find out more about BAURO-MATE contact us below

Pick & Place FAQ's

A pick and place machine does exactly what it says on the tin. Using a programmed robot, the system collects a part from one place and moves it to another part of the production line.

These robots are programmed through a teach pendant like all industrial robots. A bit like a tablet, the teach pendant controls all aspects of the industrial robot. When being programmed, the users control each axis, moving the robot from point-to-point and recording each move. These are saved into a program and can be run automatically by the industrial robot over and over again.

These robots can work far quicker than traditional manual techniques at moving parts from A to B, working continuously over multiple shifts to help businesses grow and become more efficient.