Automated Dispensing

Struggling to automate your dispensing process? Need to find a robot to aid your riveting or are you just looking to find ways to automate your bonding processes?

It’s likely that you’ve come across many automation companies with a ‘one solution fits all’ approach, but that’s never the case.

Dispensing, riveting and bonding is no different and you need to be sure that the decisions you make reflect the requirements and direction of your business. We’ve tried to answer the key questions surrounding this particular area of manufacturing so you get the best possible results; let’s take a look.

Stick with Automation

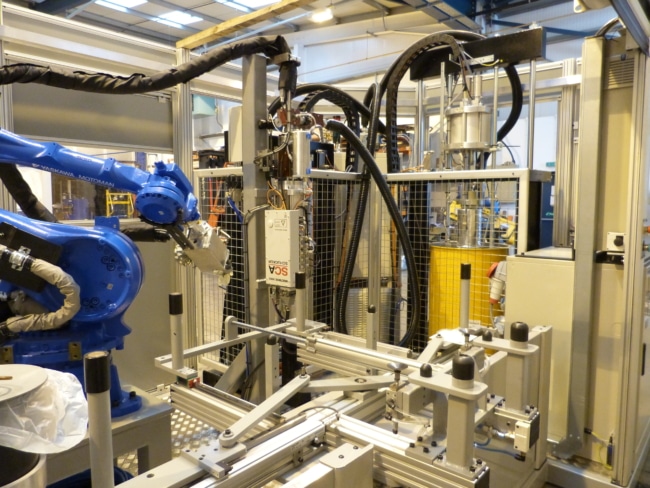

Whatever bonding & dispensing automation your application requires, we can integrate a robotic system to suit your specifics. Cost-effective and highly accurate, we can design your system to suit any range of techniques, size or specification. Whether it’s the joining of two separate parts or the application of a substance as part of a larger production line. Using our years of experience and by working closely with our partners, we can also help refine the process, whether in the selection of a technique or in the trialling of the process.

With examples of automated dispensing and bonding used in a leading automotive company’s manufacturing lines, as well as throughout other production lines in various industries, Bauromat has a fantastic track record in providing automated dispensing and bonding.

What Are Dispensing Robot Systems?

Robotic dispensing systems are fully automated machines that can enhance the quality of the dispensing for your manufacturing process while also maintaining a consistent level of quality for your parts.

While there are no specific robots to use for dispensing, it completely depends on the scale of your requirements. The higher the volume and larger the parts, the more material needs to be dispensed. Typically this would mean that a larger robot would be needed. Compare this with small run-offs and your dispensing robot options may vary.

Dispensing robot systems can be a valuable part of your manufacturing process and help your business stay ahead of your competitors.

Automatic Riveting

Where joining materials together is required, but welding may be too harsh to the material, riveting provides an alternative solution that can warrant similar results. In a world of developing technologies, Bauromat is at the forefront of changes and when some manufacturers choose to move over to automated riveting methods over traditional welding solutions, Bauromat has the experience to provide solutions for any variations.

Bauromat works closely with self-piercing rivet equipment manufacturer Henrob to ensure quality products are used in all automation solutions. Self riveting automation provides the perfect answer as an alternative solution to welding when the material might not cope well with the high temperatures.

Automated Dispensing Vs Manual Dispensing

It’s very easy to assume that automated dispensing is a quicker, more efficient and consistent form of dispensing when compared with manual. While that is certainly the case, you have to step back and look at the bigger picture and the project as a whole.

If you very rarely require dispensing as part of your manufacturing process, investing in an automated robotic dispensing system isn’t going to be a good investment. If your volumes are high and you need consistent quality levels, automated robotic dispensing is the approach to consider.

Speak to an automation system provider to discuss your requirements and discover if you needed automated or manual dispensing.

BAURO-MATE

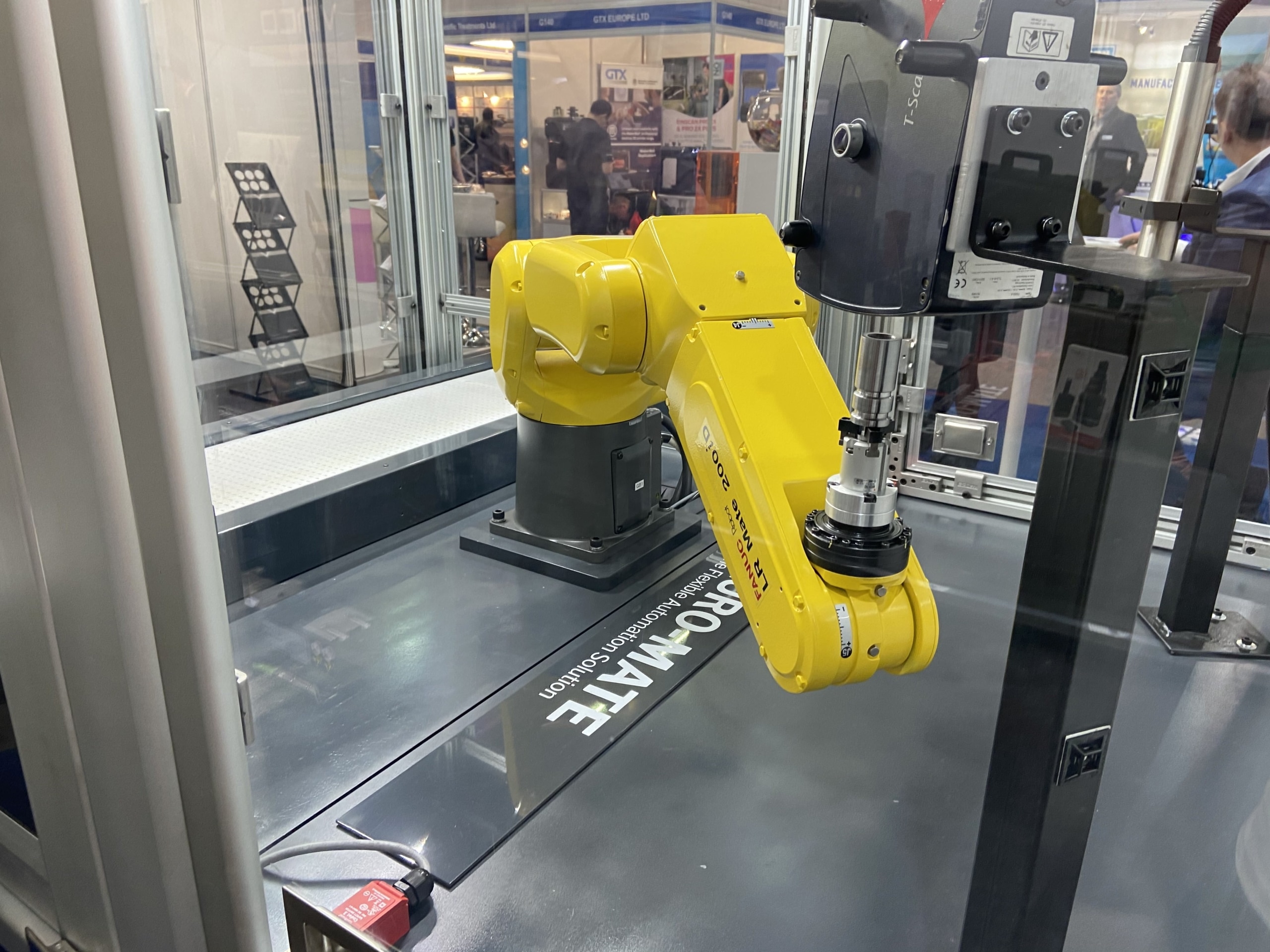

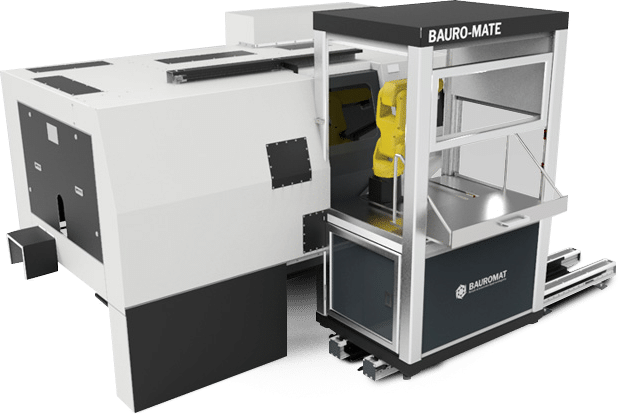

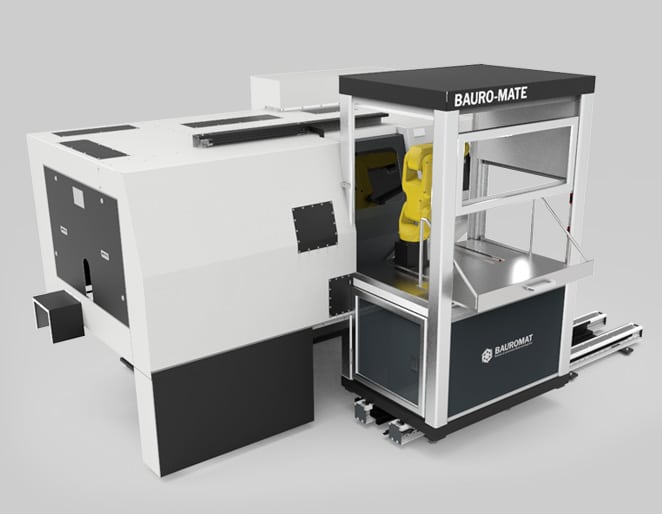

For small-sized applications, Bauromat’s BAURO-MATE can be the ideal solution. Designed to integrate existing dispensing or bonding heads or manufactured for an entirely new process, BAURO-MATE is entirely flexible and can be designed to suit any and all possibilities.

Dispensing and bonding make perfect use of the BAURO-MATE’s split-half design, too. With the robot fixed in an open-sided half, if there are multiple processes in your production line, you can make cost savings by having multiple application halves with the use of only one robot.

Industry 4.0 Levels of Service

Bauromat’s philosophy of ‘integration from day one means that the end-user will receive the highest level of service from initial conversations, through to design, manufacture, installation and commission. The automated solution will be built with the customer’s requirements at the heart of every decision, with everything from the type of robot, brand and type of process being made especially for your requirements.

On top of this, all Bauromat systems, be they standard or bespoke come with a unique industry 4.0 HMI system, designed entirely in house from the ground up the system helps monitor and control all aspects of the system at all times

Can You Get Robots For Riveting?

Robots can be used in all aspects of manufacturing and riveting is no different. While there are no dedicated riveting robots, most robots across all manufacturers can be used for the process.

It all comes down to two factors. Firstly, what system are you using for the rivets? If the equipment is particularly large or can only be integrated with certain types of robots, this will guide your decision.

Secondly, the robots to consider for riveting comes down to your volume. How many parts need to be riveted? How large are they? This will help paint a clearer picture of the riveting robot that you will require.

What Ways Can You Automate The Bonding Process?

Bonding can be an important part of the manufacturing process. Whether through traditional industrial means such as welding or riveting, or via techniques such as gluing, automating is a fantastic way to speed up the process. Beyond this automation also helps improve the quality levels, producing parts to the highest standards.

Finding ways to automate is a great way to achieve these benefits and it starts with finding an automation partner. Experts in the field of automation will be able to discuss your options, whether that’s through introducing robots to your manufacturing process, or finding new, more modern bonding techniques.

How To Find The Best Automated Dispensing System

The best automated dispensing systems are those that are the result of collaboration between the system provider and the end user. Only through this approach can both parties truly understand the advantages and what each other is trying to achieve.

Talking through your requirements and expectations, and working on a solution together is the only way to really get the best results.

Combining both communication and experience is essential in finding the best automated dispensing system.

Let’s find the best Dispensing solution for you...

Dispensing, Bonding & Riveting FAQ's

Dispensing robots, like all industrial robots, are controlled & programmed through a teach pendant that allows the robot to be moved between positions. These are recorded and then used automatically by the robot. Dispensing robots also features automatic dispensing heads which would be programed to dispense at particular points in the robot's cycle.

Through the application of extreme pressure, when riveting two materials together the rivet expands forming a bond between the materials that are extremely durable. Riveting is becoming a great alternative to traditional spot welding techniques in the electric vehicle industry.

All robot systems will feature an industrial robot and control, either floor or base mounted. Depending on the job the robot system is doing depends on what components can feature, ranging from dispensing units, rivet guns or welding equipment. All robotic systems should be entirely guarded to protect operators and machinery.