How Automation Training Helped KME Improve Their Output

Shouting out about robotic automation and the savings and efficiency it can bring to your manufacturing business is one thing. But actually seeing the benefits come to fruition is another.

It all comes down to one thing. Automation training.

Having an automation system delivered on site is one thing, but being trained to use it correctly and having the ability to control it, react to any issues that arise, and maintain it to the highest possible standards is something entirely different.

One of the best examples of this is from our friends at KME Steelworks. In purchasing a fully automated robotic system and having all the subsequent automation training, KME experienced a huge improvement in part cycle time.

Read on to find out more.

Why Automation Is Needed?

Northern Ireland based manufacturer KME was suffering from a shortage of labour.

Turning to automation, they realised it was the only solution to maintain the high demand of its own customers without continuing to have a regular turnover of staff.

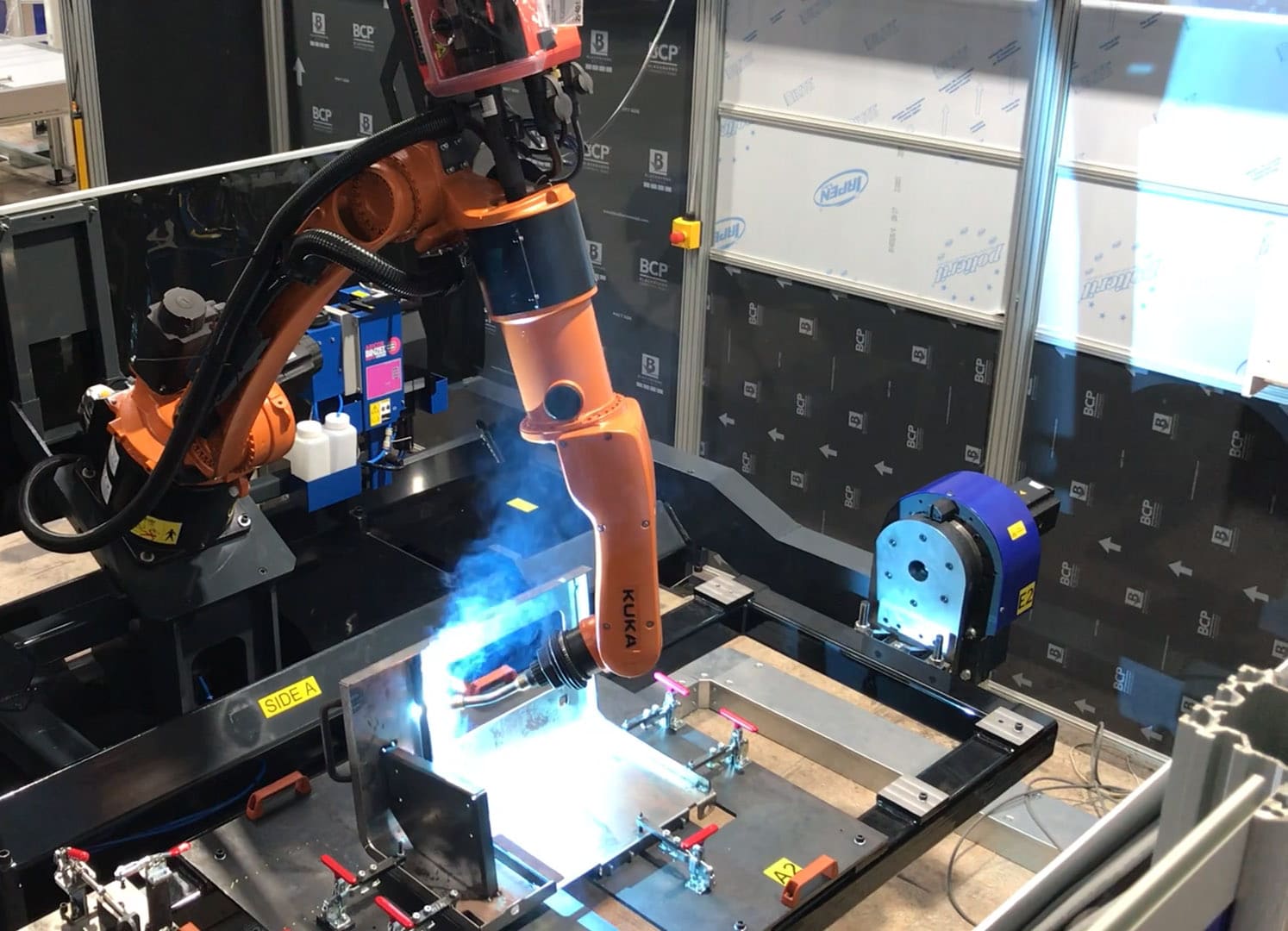

Following automation trials to test various methods of welding, a system was purchased consisting of a KUKA KR6 arc welding robot, Fronius TPS 400i weld set and Binzel cleaning set. Based on Bauromat’s standard BAURO-Arc 400 welding system, you can find out more about the KME system here.

But with the system in place, KME’s automation endeavours were far from over and training was also required.

Automation Training

Offered with every automation system, almost as a prerequisite, automation training is essential to making sure you can get the most from your robotics.

So much so, that due to its importance, training is also offered at any stage of the automation system’s life; from first timers, to experienced automation stalwarts, we encourage every manufacturer to explore training regularly as a means of sharpening knowledge and refining skills.

KME opted for 3-days of training for 3 of it’s engineers and the people who would be working alongside the machine.

From the basics of learning how to program the robot and understand how all the axes work together, to the fundamentals of the automation system as a whole, in less than a week the KME team became experts in automation operation.

This meant that when the system was finally delivered, both Bauromat and KME were safe in the knowledge that there were no gaps in education and the system could operate to its full potential.

The Results of Trained Automation Experts

With the system installed across the Irish sea, KME instantly began to see an increase in efficiency. An 65% cycle time saving wasn’t only down to the automation system as a whole, it was down to the training, too.

Because the KME team had extensive knowledge and knew what to do in various scenarios, they could react and immediately resolve any issues, big or small, quickly and efficiently, rather than ringing for phone support or arranging an on-site visit.

Not only did this save time, but it helped save money and needless spending too.

Conclusion

It goes to show the importance of automation training.

You can spend all the money in the world on the best possible automation system with all the bells and whistles, guaranteed to get your manufacturing business running more efficiently, but without automation training, it’s worthless.

A lot is said about robots taking jobs, but you can see that without human operators they are nothing. The two very much rely on each other.

Automation training means that you can maintain the automation system and ensure those benefits you are constantly told about actually occur.

If you’d like to book some automation training time or better understand the function of your new or existing system, speak to our expert team today.

Send us your question & let us know how we can help you

Bauromat

Stafford Park 6

Telford

TF3 3AT

United Kingdom